-

News

Jackson County 911 callers can now utilize video for improved assistance

Above: Dispatchers take calls at Jackson County Central Dispatch. Jackson County Central Dispatch keeping up with technology By Julie Riddle...

-

Business

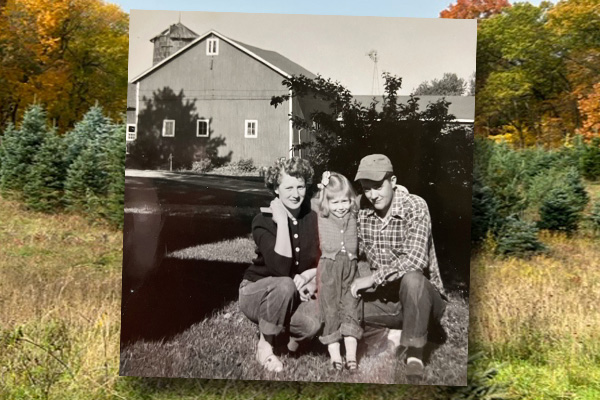

Granny D’s Christmas Tree Farm still going strong

Above: Jeannine, Cathy and Charles Doan are shown in this old family photo. Hello Neighbor By Sheila Cote To...

-

News

How wheelchair friendly is Brooklyn?

From left: Brian Elliott of Disability Connections, Glen Ashlock, WellWise Area Agency on Aging; Patti Robinson, Brooklyn Village Council;...

-

News

‘We’ve got one chance’

$10 million in lawsuit settlement funds to address troubling drug trafficking, addiction problems in Jackson and Lenawee counties By...

-

News

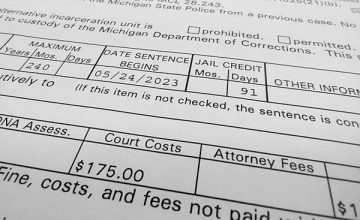

Attorney: Choate case ‘a clear abuse of power’

Above: Hank Choate, who has been accused of election fraud, makes a point while his attorney, David Kallman, listens....

-

Community

Hello Neighbor: Meet Hollis and Willow Jeffreys

Above: Hollis and Willow Jeffreys have a long history in the Brooklyn and Onsted communities. By Sheila Cote Even...